-

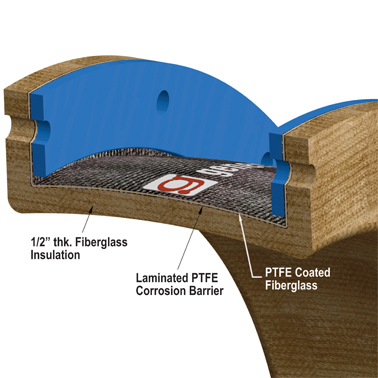

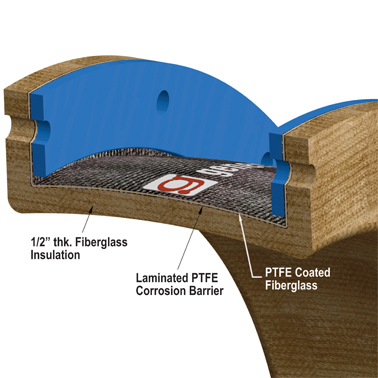

18" ID Style 1093 PTFE single layer ducting expansion joint cross-sectional detail

-

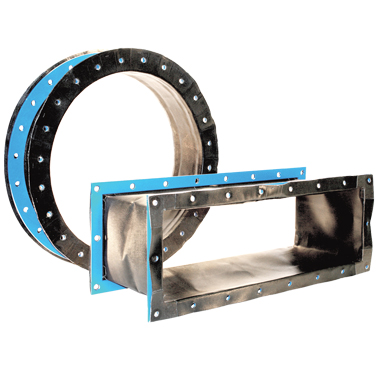

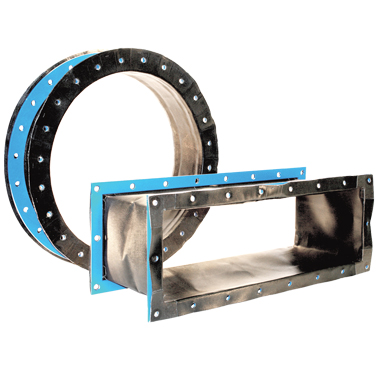

Round and rectangular Style 1093 PTFE single layer ducting expansion joint sample

-

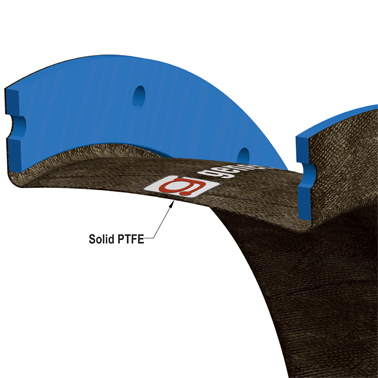

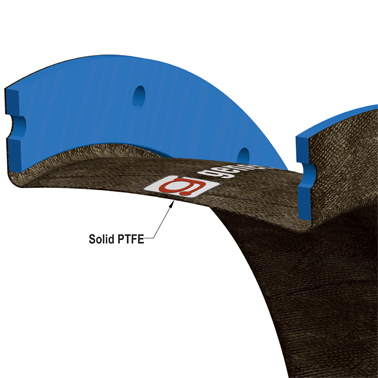

18" ID Style 1094 PTFE single layer ducting expansion joint cross-sectional detail

-

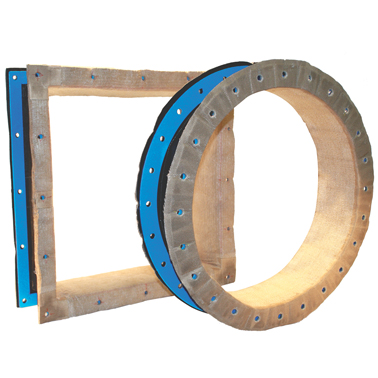

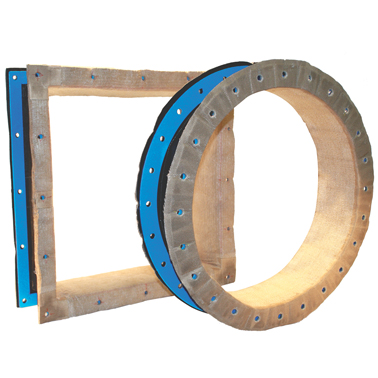

Round and rectangular Style 1094 PTFE single layer ducting expansion joint sample

-

18" ID Style 1095 PTFE single layer ducting expansion joint cross-sectional detail

PTFE Single Layer

Styles 1093 & 1094 & 1095

General Rubber’s Styles 1093, 1094 and 1095 PTFE single layer flanged ducting expansion joints are designed with lower spring rates for reduced reaction forces and greater movement capabilities within a compact body. This lightweight construction is optimally designed with external or internal laminated flanges and represents the most cost-effective arrangement for low pressure flanged ducting applications. The construction includes a PTFE fluoropolymer laminated flexible element and steel retaining rings. Additionally, they are designed to absorb large all-directional movements, reduce noise and vibration, compensate for misalignments, provide access to ducting and equipment and relieve duct and anchor stresses.

General Rubber’s Style 1093 offers up to 600°F with ± 3 PSI continuous service and zero porosity in wet and dry systems. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement and a 9 Mil thick laminated PTFE fluoropolymer corrosion barrier.

General Rubber’s Style 1094 offers up to 1,000°F and ± 3 PSI continuous service. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement, laminated PTFE fluoropolymer corrosion barrier and a laminated woven or needle mat fiberglass insulation layer.

General Rubber’s Style 1095 offers up to 500°F with ± 3 PSI continuous service, zero porosity in wet and dry systems and a cycle life in the millions. The flexible element is constructed of a solid 30 Mil thick PTFE fluoropolymer layer and is available in thicknesses up to 60 Mil; offering the ultimate chemical resistance with no fiberglass component to fatigue.

General Rubber’s Style 1093 offers up to 600°F with ± 3 PSI continuous service and zero porosity in wet and dry systems. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement and a 9 Mil thick laminated PTFE fluoropolymer corrosion barrier.

General Rubber’s Style 1094 offers up to 1,000°F and ± 3 PSI continuous service. The flexible element is constructed with PTFE fluoropolymer coated high tensile fiberglass reinforcement, laminated PTFE fluoropolymer corrosion barrier and a laminated woven or needle mat fiberglass insulation layer.

General Rubber’s Style 1095 offers up to 500°F with ± 3 PSI continuous service, zero porosity in wet and dry systems and a cycle life in the millions. The flexible element is constructed of a solid 30 Mil thick PTFE fluoropolymer layer and is available in thicknesses up to 60 Mil; offering the ultimate chemical resistance with no fiberglass component to fatigue.

Features

- Round and rectangular designs in all styles

- Laminated PTFE fluoropolymer corrosion barrier

- Reducers and offset styles available

- Exceptional all-directional movement capability

- Absorbs system noise, vibration and shock

- Compensates for minor misalignment and offset

- Available with external or internal flanges

- Low stiffness and deflection forces

- Simple to install, lightweight and high strength

- Provides easy access to ducting and equipment

- Carbon steel, stainless steel, or hot dip galvanized backup rings available for easy bolting to mating flanges

- Superior chemical resistance

- Heat form and sealed to any size and arrangement