-

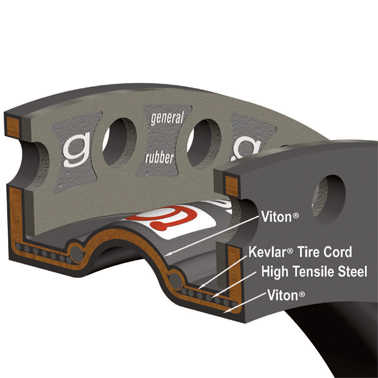

36" ID X 10" FF Style 1101HT high temperature rubber expansion joint

-

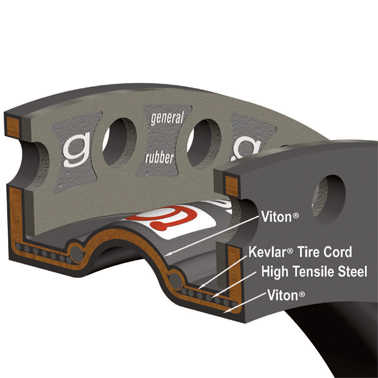

36" ID X 10" FF Style 1101HT high temperature cross-sectional detail

-

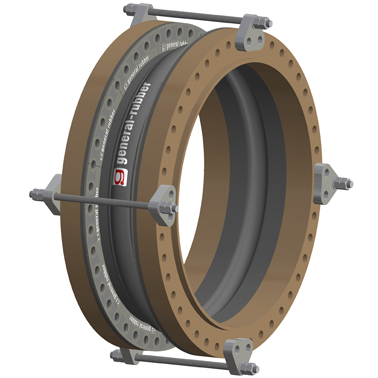

48" ID X 12" FF Style 1101HT high temperature assembly with W/B 4-rod control unit

-

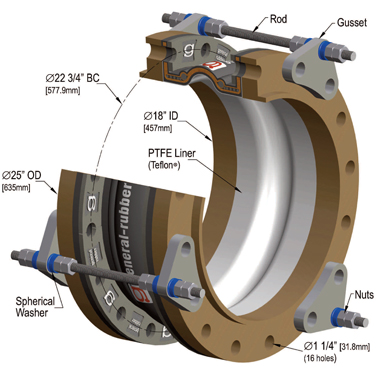

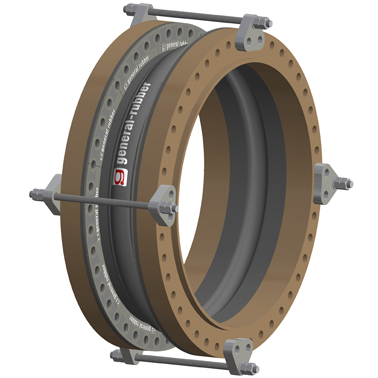

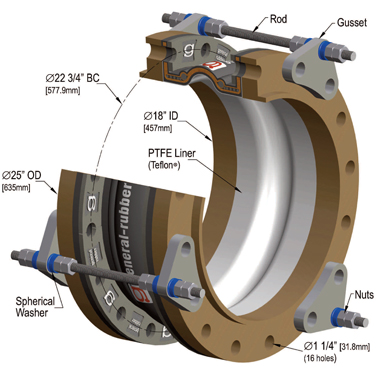

18" ID X 8" FF Style 1101HT high temperature assembly with SW/SW 3-rod control unit and optional PTFE liner

-

72" ID X 12" FF Style 1101HT high temperature with INT-WB integral gusset/retaining ring control unit

High Temperature

Style 1101HT

General Rubber’s Style 1101HT rubber expansion joints are designed for higher temperature applications. The spool type body is constructed with a high temperature resistant EPDM or Viton® leak-proof tube and seamless cover with Kevlar® high temperature and high-strength tire cord reinforcement. The construction includes full rubber flanges, high tensile steel reinforcement and hot dip galvanized steel retaining rings. Additionally, they are designed to reduce noise and vibration, have a cycle life in the tens of millions, compensate for misalignments, provide access to piping and equipment and relieve pipe and anchor stresses. This construction, as a standalone expansion joint, represents the most cost-effective arrangement when used in rigid piping systems with main anchors (MA) and numerous guides at specific spacing. Control units can be externally or internally attached and used as limit rods for secondary restraint or as tie rods when the support structure or adjacent equipment have load limitations.

Features

- Versatile hand-built construction

- Standard or custom face-to-face dimensions

- Available in multiple arches or custom offset arrangements and sizes not shown

- Virtually eliminates sediment buildup

- Absorbs noise, vibration and shock

- Higher pressure rating than conventional expansion joints

- 350°F continuous service with EPDM / Kevlar®

- 400°F continuous service with Viton® / Kevlar®

- Excellent chemical and abrasion resistance

- Full vacuum rating (30″ Hg) in all single arch sizes

- Hot dip galvanized retaining rings standard

- Integral flange design, no gaskets required

- Filled arch design available

- High strength and simple to install