Reduces Noise and Vibration

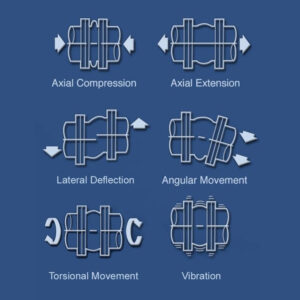

Expansion joints are primarily used to absorb all directional piping movements as well as reduce noise and vibration. In addition, they are a cost effective means to relieve piping and anchor stresses, compensate for misalignment, and provide access to piping and equipment.

Absorbs all Directional Movement

Reduces Noise and Vibration

High Resistance to Fatigue and Shock

Our abrasion and corrosion resistant materials can be superior to even the most exotic materials. General Rubber is proud to offer a variety of elastomers and construction materials chosen specifically to meet the needs of even the most demanding applications.

Thermal movements along with other external forces and displacements, including ground settlement can quickly exceed allowable pipe and anchor stresses. General Rubber expansion joints absorb these stresses and replace them with their own low stiffness (spring rate).

It is common in both new construction and replacement applications to encounter pipe misalignment. Minor misalignment can be taken up with standard General Rubber expansion joints, and custom units can be quickly fabricated with large permanent offsets.

Access to piping and equipment can be easily achieved by treating the expansion joint as a removable spool piece. If a self-retracting design is needed, General Rubber’s Style 5100D dismantling joint can be utilized.

An optimal design does not necessarily mean higher pressure or temperature ratings, because these features typically increase the product’s stiffness and cost. With a proven track record that dates back to 1950, General Rubber has the experience and is confident that we can develop an optimal and cost effective solution to meet your requirements. Our abrasion and corrosion-resistant materials can be superior to even the most exotic metals. Our large inventories and modern U.S. ISO 9001 & 14001 certified manufacturing facility also mean quick deliveries, as well as top quality products and services.