Expansion Joints may operate in pipelines and ductwork, or incorporated with equipment carrying fluids and/or gases at elevated temperatures and pressures, and may transport hazardous materials. Precautions should be taken to protect personnel in the event of leakage or spray. Expansion joints should only be installed where inspections are possible. Expansion joint installations should be conducted by authorized and qualified personnel.

Service Conditions & Inspection

Check that the temperature, pressure, vacuum and movement ratings for the expansion joints are not exceeded by system conditions. Also verify that the expansion joints’ elastomers are compatible with the process fluid or gas. If any of these ratings are exceeded, contact GRC immediately. Visually inspect expansion joints for cuts and gouges from transport or worksite handling prior to installation.

Alignment

Expansion joints should not be used to rectify piping/ducting misalignment of more than 1/4” [6.4mm]. Exceeding allowable misalignment value may cause damage and void the warranty. Misalignment will detract from rated movements. The use of support and guides may be required to maintain proper alignment and support the weight of the pipe and ductwork. Note: GRC can fabricate expansion joints with built-in offsets to accommodate field dimension variances.

Anchoring

Verify that the system anchors, supports and guides, are in accordance with the piping/ducting system drawings. Any field variance from planned installation may affect the expansion joint parameters, reduce life expectancy and heighten the above stated warning.

Mating Flanges

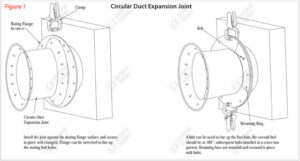

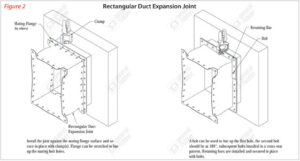

The mating flanges or expansion joint attachment area of the pipe, ductwork and equipment must be smooth, clean, flat, and parallel. All welded areas must be ground smooth at the attachment points. The area around the expansion joint must be cleared of any sharp objects and protrusions. It is recommended to install bolt heads against the Retaining Ring/Bars and use SAE-sized washers at the retaining ring split. Care must be taken to ensure the retaining ring ends butt up to each other without over-lapping or allowing a large gap between ends. Expansion joint installation can be facilitated by choosing the difficult flange to bolt up to first. The expansion joint flange can be pushed into position from the inside body out. Insert a bolt through the first hole and install the subsequent bolts in a cross-star pattern and tighten by hand (see figures 1 & 2). Repeat the steps for the opposite flange.

Bolting Torque

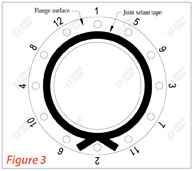

Tighten bolts in stages by alternating around the flange in a star pattern until a leak tight seal is achieved (see figure 3). If the expansion joint has an integral rubber flange, the bolts should be tight enough to make the outer rubber flange bulge slightly between the retaining ring and the mating flange. Avoid using any rubber gaskets. Expansion joint flanges may have to be retightened after initial installation due to the rubber flanges relaxing and taking a compression set. If the expansion joint has an integral laminated fluoroplastic PTFE flange, a PTFE joint sealant tape should be applied onto the mating flange to improve sealing. Ensure the placement of the joint sealant is below the bolt circle diameter as shown on figure 3. Check bolt tightness two or three weeks after installation and retighten as needed. Never retighten bolts when the pipeline/ducting is under pressure.

Maintenance

Expansion joints should be inspected regularly to insure they are in proper working order. Check the face-to-face dimension for any changes and make sure it is still within allowable limits. Look for any obvious bulges, tears, cracks or other damage. If there are any signs of damage, contact GRC immediately.

Storage

Ideal storage is a cool and dry warehouse location. Store flange face down on a smooth pallet or wooden platform. Do not store other heavy equipment on top of the expansion joints. If storage must be outdoors, the expansion joints should be placed on smooth, wooden platforms and should not be in contact with the ground and/or exposed to vermin. Cover with a tarpaulin or store in original container.